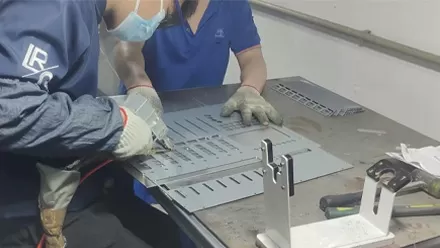

Welcome to Pinzhihao Precision Manufacturing Co., Ltd., a beacon of precision and excellence in the world of custom machining. Established on October 12, 2023, in the bustling city of Bac Ninh, Vietnam, Pinzhihao Precision Manufacturing has rapidly emerged as a leading force in the CNC machining and sheet metal processing arena.

Full-Process Quality Control

1. Incoming Quality Control (IQC)

Verification of material specifications and certificates

Inspection of thickness, dimensions, flatness, and surface condition

Confirmation of quantity and storage conditions

→ Ensuring only qualified materials enter production

2. First Article Inspection (FAI)

Full dimensional inspection based on engineering drawings

Verification using calipers, micrometers, CMM, and dedicated gauges

Confirmation of CNC programs, bending parameters, and tooling setup

→ Mass production begins only after first-article approval

3. In-Process Quality Control (IPQC)

Periodic measurement of key dimensions and tolerances

Monitoring of tool wear, bending angles, welding quality, and forming details

Real-time data tracking throughout production

→ Maintaining stability and consistency during batch manufacturing

4. Final Quality Control (FQC)

Complete dimensional verification of finished parts

Surface inspection: finish quality, coating thickness, weld appearance, cleanliness

Fit and assembly testing to ensure full functional compliance

→ Only products that meet all specifications proceed to packaging

5. Outgoing Quality Control (OQC)

Sampling to validate overall batch quality

Inspection of packaging protection, labeling, and accessory completeness

Recording of traceability codes and shipment documentation

→ Guaranteeing that every shipment reaches customers in perfect condition